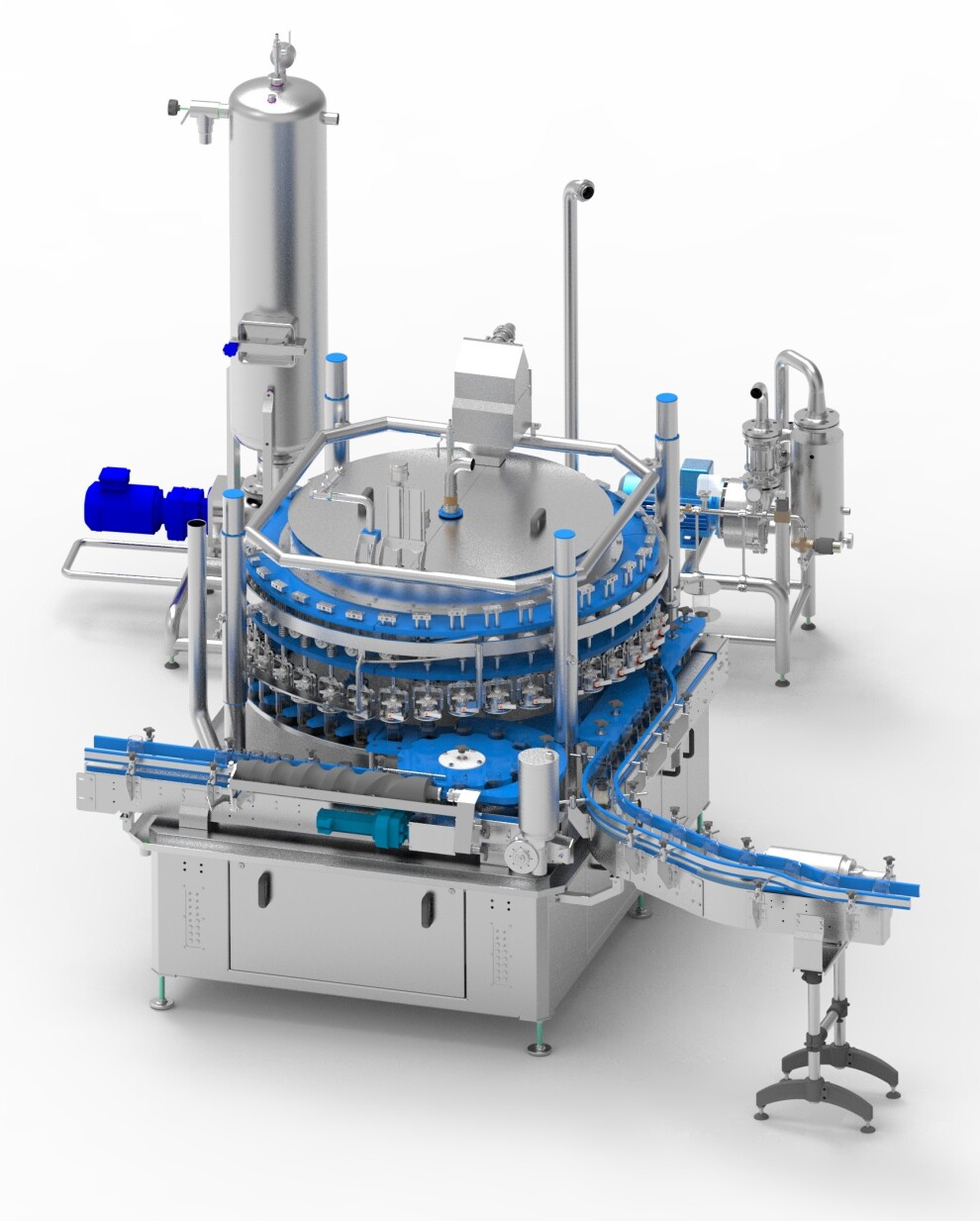

Vacuum Filler

For overflowless filling of containers with liquid to pasty products under vacuum. No contamination, no foaming, no product loss, low wastewater pollution. During the passage through the machine, the containers are first evacuated and then filled with air bubbles by automatically switching the valves with the product. Complete emptying (oxygen) of the containers - even with tightly packed products, thereby avoiding oxidation of the product (discoloration, vitamin loss).

With different machine sizes and amount of filling heads, reaching max. outputs of approx. 425/min, depending on product and containers.

Special versions are also available for gassing pre-filled containers, for example with nitrogen, to extend the shelf life of stacked chips, nuts or other products.

The machine completely consists of Cr-Ni-steel 1.4301 / 1.4404 (AISI 304/316) or any other stainless material, such as plastics, with the exception of drive and bearing components.

Possible equipment features:

-

No containers - no filling

- Filling temperature up to approx. 80°C

-

Even headspace due to space-defining disk (exchangeable)

- Infeed section with spring loaded recognition for tilted containers and safety shutdown

- Motorized height adjustment

- Execution with servo-technology, for reducing of intersection tolerances / elimination of gearboxes wearing out

- Motors in clean design execution of stainless steel, possibly capsuled

- Vacuum water ring pump

- Vacuum separator tank, for collection and return of exhausted product

- Jog control for set up of machine

- Thermal insulation of product / separator tank

- cleaning nozzles pipe with magnet switch valve, for precleaning

- tangential outfeed of containers for smoother flow in cases of higher outputs

-

Also in combination build-up with headspacer or volume filler, or with a can seamer (combi-block)

You and niko - Let's plan our joint project now.

With niko at your side, you can look forward to successful cooperation and optimal production in the food industry. Our wide range of products, our custom-fit solutions and our first-class support will help you achieve your goals. Contact us now and let's work together on your future.

Contact us now!